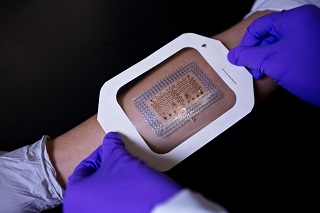

A team of researchers at the University of Texas at Austin has developed a new manufacturing process for flexible electronics that could represent a major step forward for ultra-thin tattoo-like health sensors.

A team of researchers at the University of Texas at Austin has developed a new manufacturing process for flexible electronics that could represent a major step forward for ultra-thin tattoo-like health sensors.

Flexible, stretchable electronics are a burgeoning field of interest that many see as the next generation of health monitoring after wearables. Disposable devices that adhere to your skin, like temporary tattoos, could provide a seamless monitoring experience and a lot of work has already been done to create miniaturized, accurate sensors. Just last month, the Department of Defense poured $75 million into a consortium (which includes UT Austin) developing this technology.

Assistant Professor Nanshu Lu's breakthrough, which was published in Advance Materials, would allow these sensors to be manufactured more cheaply and easily than they currently can be. It would reduce the process from a matter of days to a matter of minutes and eliminate the need for expensive resources like clean rooms and wafers.

"One of the most attractive aspects of epidermal electronics is their ability to be disposable,” Lu said in a press release. “If you can make them inexpensively, say for $1, then more people will be able to use them more frequently. This will open the door for a number of mobile medical applications and beyond.”

The manufactured patches, created quickly through a roll-to-roll method, performed better than existing medical devices on picking up vital signs like heart rate. The team is still experimenting with adding additional sensors, like those for blood pressure and oxygen saturation, to the low-cost patches.

Lu is also the co-founder and scientific adviser for Stretch Med Inc, a stealth mode company working on commercializing these developments.

A number of researchers are working on this technology including a team at University of Illinois at Urbana-Champaign and Northwestern University led by Yonggang Huang and John Rogers and one from North Carolina State University led by Yong Zhu.